The machine has a unique, innovative compact design that allows easy installation in many tight spaces. The corrosion-resistant stainless steel cabinet frame has a modular design that divides the system into multiple clusters for easier installation.

The SWS product line is equipped with premium components including:

The capacity is 300-500-1.000 liters/hour and the maximum water supply TDS is 42,000ppm.

Filter sea water into fresh water and drink directly at the tap, ensuring that it meets the standards of pure bottled drinking water (QCVN 6-1:2010/MOH.)

Small capacity seawater purifier is used for:

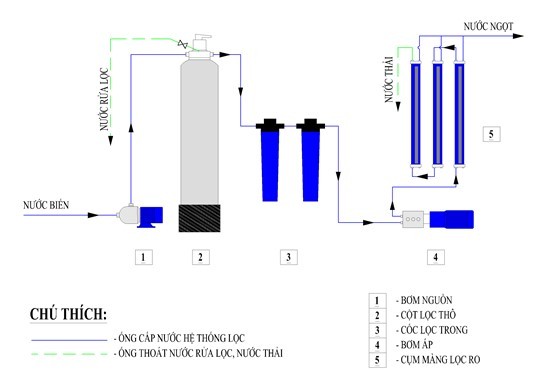

The machine works by using specialized RO membrane technology and 60bar high-pressure pumps, resistant to the corrosion of seawater. The pump pushes seawater through RO membranes with micropore sizes to form pure fresh water that can be drunk directly. Part of the seawater that does not penetrate the RO membrane will be carried away with the impurities discharged into the sea.

|

2. Main machine components: - Low pressure switch. - Handheld TDS meter. - Pipe fittings plastic, stainless steel. - Stainless steel throttle valve. - Stainless steel rack. - 20 inch PP pre-filter 02 cores. - High pressure reciprocating pump resistant to seawater corrosion. - High-grade electrical control cabinet. - Finished water flow meter. - Specialized RO membrane. - FRP membrane shell. - Power supply 220V(1P) 380V(3P) 440V(3P)/ 50Hz (60HZ). - Inverter control pump. - Electronic pressure gauge: - High pressure switch. - Coarse filter column. |

Optional List: - pH raising Column - Online TDS meter, displayed on LCD screen. - PLC programmer, HMI . screen

|

Help us improve our product and service quality by submitting your personal review via the form below:

Compare with similar products

Can Karofi advise you on water purifiers?